27

Officelayout 156

gennaio-marzo 2014

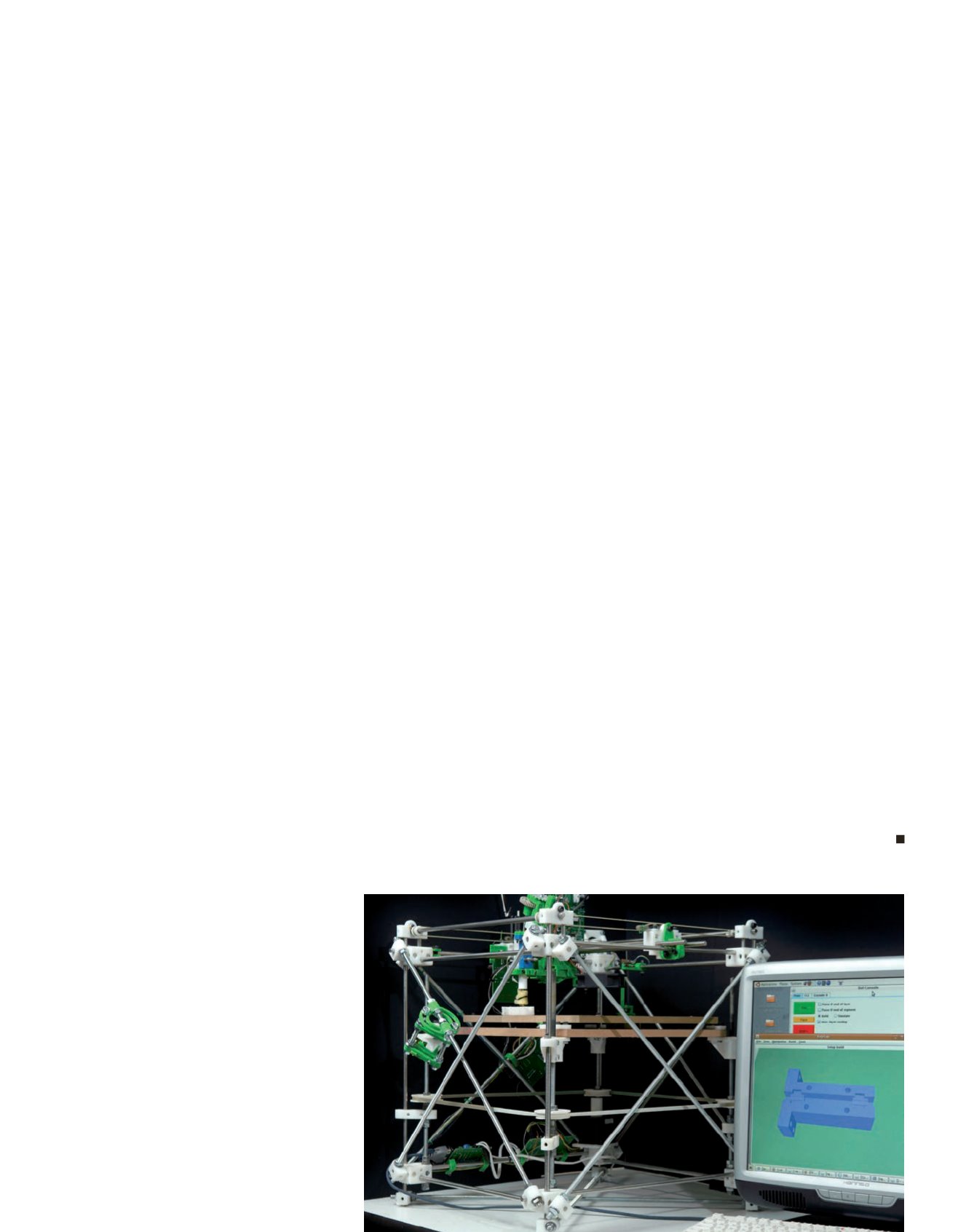

Opportunities and challenges of 3D printing

Created as a tool for rapid prototyping, 3D printing has emerged as a production technique for the construction

of finished products, with remarkable advantages for creativity and the possibility of inventing and experimenting

with very low costs

3D printing is a process of production of three-

dimensional objects, that starting with a digital

model permits the creation of complete objects or

parts. It is a technique of additive production

that constructs objects by adding material

through a process of sequential layering, rather

than removing portions of material as happens

with traditional machine tools.

The advantages are the reduction of the

quantity of material used in fabrication

processes, and the possibility of creating

objects that would be hard to make with

traditional techniques.

The materials used are plastics, metals,

ceramics, clay and sand, glass, wood paste,

paper, chocolate and even living cells (bio-

printing). These raw materials are used by the

printers in the form of liquids, powders,

filaments or sheets.

The finished products offer a range of benefits,

because they can be lighter while remaining

sturdy, can have forms that could not be made

with other production processes, can be

multicolored without the need for successive

painting operations, and can lead to products

manufactured in a single phase, rather than the

assembly of multiple parts. Since each object is

individually produced, 3D printing is an ideal

solution for mass customization and the

creation of personalized objects.

Until 2010, due to lack of availability of

materials with suitable characteristics, the

objects produced by 3D printers could not be

made as finished products, because of their

inadequate physical properties (strength, heat

resistance, surface finish, color, etc).

Over the last three years the printers and

materials have made giant steps, and the costs

of purchasing and use have been drastically

reduced, making this system feasible on a

purely economic level, for the production of

certain types of objects in specific markets

using additive technologies.

Many companies have already adopted this

technology as part of the design process,

gaining a series of advantages:

- more innovation (the possibility of printing

prototypes, perfecting designs and repeating the

cycle in just a few hours);

- better communication (a realistic full-color 3D

model has greater informative content than a

computer image);

- shorter time-to-market (the 3D printing of

prototypes to order slims design and

production cycles);

- lower development costs (reduction of costs of

prototyping, early identification of design

errors, reduction of movement to and from

production plants);

- acquisition of new clients (the possibility of

demonstrating realistic 3D models to potential

clients, sponsors and stakeholders).

3D printing is therefore emerging as an

innovation that could radically change our

approach to design and, obviously, to the

market as well.

This new technological frontier will be

analyzed by Officelayout in a series of

articles to explore the implications of 3D

printing for design and architecture, in

terms of projects and prototypes, and the

possibility of producing functioning objects.

Applications and markets

3D printing offers an advantage from the

viewpoint of creativity, because it grants the

possibility of inventing and experimenting at

very low costs. To reproduce or create any object

becomes economically advantageous, above all

if the production is limited, as in the case of

the production of prototypes and as support for

the design of innovative or particular pieces,

and in cases where more efficient service needs

to be offered to customers.

In general, it makes sense to 3D print an

object if it does not exist or is no longer

available on the market, namely when the cost

of acquisition is much higher than that of

printing, or when obtaining the object would

require too much time.

Obviously the advantages increase if the objects

produced are unique, like spare parts for vintage

cars or costly machinery and works of art.

The market opportunities are intriguing in the

field of hobbies and crafts (model making, toys,

accessories, jewelry, footwear, fashion,

ceramics, sculpture, restoration parts,

preparation of pastries), for the making of

unique or personalized objects that can be

directly produced in FabLabs, specialized

workshops or service centers.

In the field of architecture and design, 3D

printers are used for the production of urban

planning and architectural mock-ups, models and

prototypes of furniture and objects, using

different materials like steel, wood paste, plastic,

nylon, glass and ceramics. There are also

experimental projects to “print” entire sections of

prefabricated structures and buildings.

In the industrial field, the most promising

markets are the auto and aerospace industries,

precision mechanics, prostheses and other health

care devices, which require a high level of

customization and complexity. With its ability to

shorten development time for new products and

prototyping, 3D printing significantly reduces the

time-to-market of products.